What is the HACCP control?

The HACCP system refers to the Hazard Analysis and Critical Control Points of the different processes in the food industry. It is characterized by its preventive approach to food-related hazards rather than a reactive approach.

Ultimately, the HACCP system makes it possible to identify hazards and take measures to control them in order to ensure food safety.

Origin of HACCP control

The origin of HACCP controls comes from the aeronautical industry, when during the first space programs it was established as a microbiological safety control. Previously, all quality control systems were based on the analysis of the final product, with a clearly reactive focus on possible problems.

It was not until the mid 80’s those different institutions such as WHO, ICMSF, NAS, NACMCF promoted its application in the food industry.

The 7 principles of HACCP control

HACCP control is based on 7 fundamental principles:

PRINCIPLE 1: Conduct a hazard analysis.

PRINCIPLE 2: Determine the critical control points (CCP).

PRINCIPLE 3: Establish a critical limit(s).

PRINCIPLE 4: Establish a monitoring system to control the critical control points.

PRINCIPLE 5: Establish corrective actions to be taken when monitoring indicates that a particular CCP is not under control.

PRINCIPLE 6: Establish testing procedures to confirm that the HACCP system is working effectively.

PTINCIPLE 7: Establish a system of documentation of all procedures and records appropriate to these principles and their application.

How to develop a HACCP plan?

To develop a HACCP plan, 12 tasks must be differentiated based on the 7 principles previously mentioned.

Step 1: Establish a HACCP team

The first activity will be to establish the scope of the study to be carried out, which will allow the team to be set up as closely as possible to the needs. This team should be composed of people from different disciplines within the organization to better identify all the critical control points.

- On the one hand, a manager or team leader should be established to convene the group and direct its activities to ensure the correct implementation of the concept.

- There must also be a specialist in the product to be analyzed and the processes it follows. This will be the person in charge of designing the product flow diagrams.

- Several specialists who are familiar with certain hazards and risks related to quality controls.

- There will be a technical operator in charge of compiling the progress and conclusions throughout the different steps taken to draw up the plan.

- Additionally, the people involved in the different processes being analyzed can be incorporated at different points in the process.

Step 2: Describe the product to be analyzed

First it is important to identify and delimit the product to be analyzed. There is a specific form to carry out this task. Information about the safety of the product, packaging method, storage, transport, shelf life and recommended storage temperatures should be included. All this information should be included on the product label.

Step 3: Determine intended use of the product

The intended use of a product will directly influence the risks to which it will be exposed. On the one hand, it will be necessary to identify whether the product will be subjected to any processing or cooking prior to consumption, as well as the characteristics of the end consumer and whether he/she is in a position of vulnerability. Finally, the possibility of improper use of the product must be identified.

Step 4: Preparing the product flow diagram

This phase should be led by the product specialist, usually a quality control manager or process engineer. This diagram will be specific to each plant and will have annotations for each different plant.

Step 5: Confirmation of the diagram on site

Once the Product Flow Diagram has been identified and designed, the other members of the team should go to the production site and check the different sections phase by phase.

Step 6: Hazard identification and analysis

- Hazard identification: In this step, all hazards, whether actual or potential, that may occur in the ingredients or stages of the product system are identified.

Generally, food safety hazards are classified into the following 3 types:

1. Biological: usually foodborne pathogenic bacteria such as Salmonella, Listeria and E. coli.

2. Chemical: these can be of natural origin, produced by microorganisms or chemical substances added by humans such as fungicides or insecticides.

3. Physical: those contaminating elements such as insects, stones or metallic fragments.

- Hazard analysis

The probability of a hazard occurring is called risk. Each probability or risk is assigned a value according to the degree of certainty as to whether it will occur. Once the probability has been established, an analysis is made of how much risk this hazard poses to people or animals. Those hazards that are finally determined as inadmissible will be transferred to the Critical Control Points.

Finally, once the hazards have been identified, control measures must be worked out. These control measures will be oriented to reduce the risks.

Step 7: Establish Critical Control Points (CCP)

In this step, the hazards previously identified in step 6 are analyzed to determine whether control measures are in place and whether they can adequately control the hazard.

If it is established that there are no adequate control measures, production of the food will be suspended until these are defined and implemented.

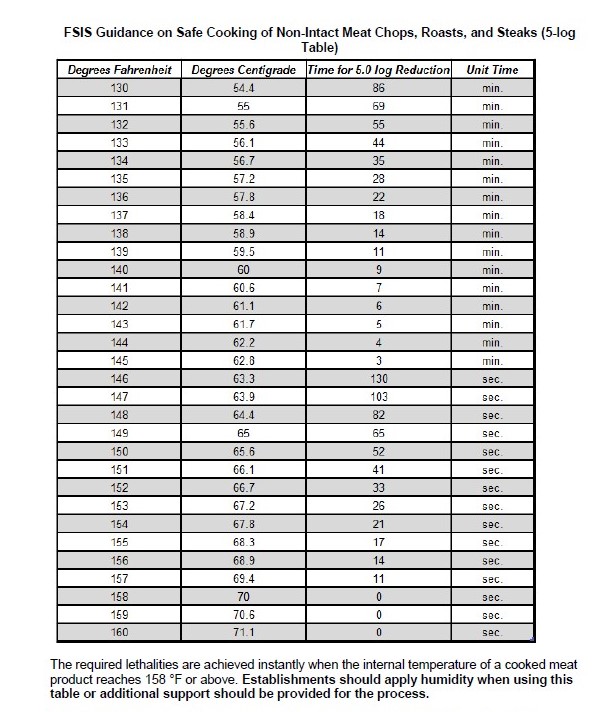

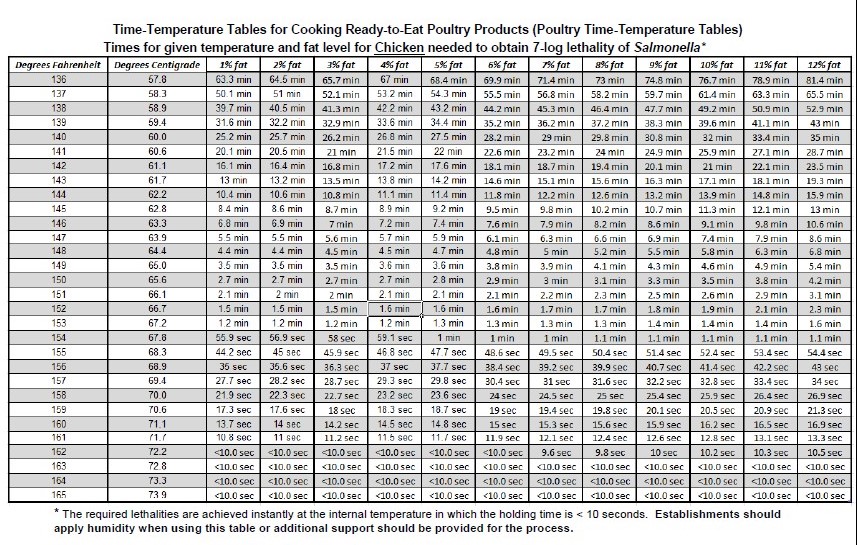

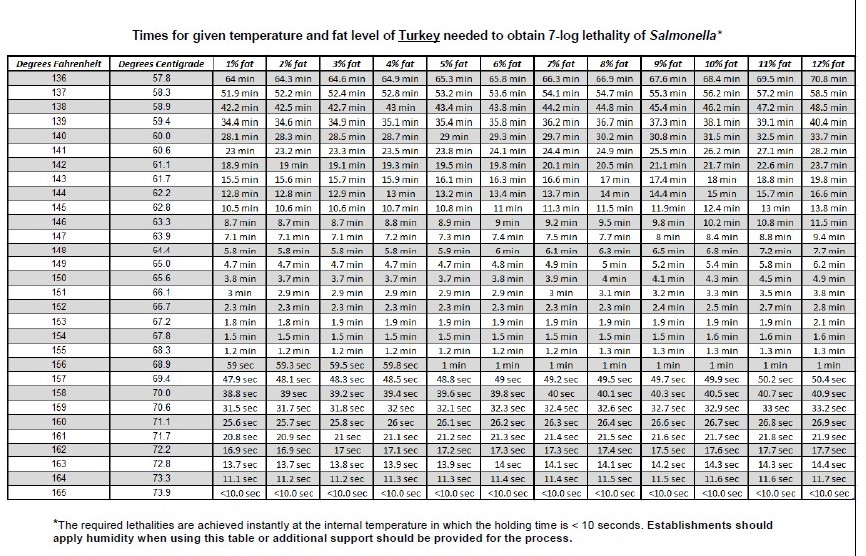

Step 8: Establish critical limits for each CCP

Critical limits can respond to different measurement criteria, such as temperature, moisture content, exposure time, pH, water activity or appearance. These measurement criteria should have established allowable levels or limits.

Step 9: Establish a surveillance procedure

By surveillance we mean the monitoring of critical control limits to ensure compliance. This surveillance should be rapid and should enable prompt corrective action to be taken.

The most common surveillance procedures refer to time, temperature and moisture content.

Step 10: Establish corrective actions

Corrective measures should be established for the most unfavorable cases. These corrective actions should be established considering the end use of the product, hazards, risks and their severity.

Step 11: Verify HACCP plan

Once the plan has been established, it is necessary to verify and validate that all hazards, limits, and corrective measures have been correctly established.

This can be done in several ways:

- To order an external audit

- Analyze samples of the product with methods other than those established.

- Periodic observations of Critical Control Point operations.

Step 12: Record keeping

Finally, we have the task of record keeping. This is a very important point since it allows to follow up the processes followed by the product, leaving a record of compliance with the critical limits.

How to carry out controls in the JANBY Track?

The Janby Track is a system that digitalizes and automates the cooking process as well as the Sous Vide regeneration process. In addition, it has a wide range of options and configurations that allow the user to set alarms and alerts that meet the control needs of each organization.

Label generation and the option of discarding batches

On the one hand, responding to principle 1 of HACCP control and to task 2 of describing the product, you have the option of generating product labels with all the necessary information using the Janby Cloud, as well as discarding batches that do not comply with regulations with a single click.

Activity logs in the Cloud

In relation to the last step of the HACCP plan on record keeping, all movements and actions that occur throughout the service are automatically recorded, as well as the time at which it was cooked, for how long, at what temperature the water was and the temperature of the probe in case it was used.

Additionally, with the option of connecting the Janby Track to the order system, we would have information of who has been the final customer of that product.

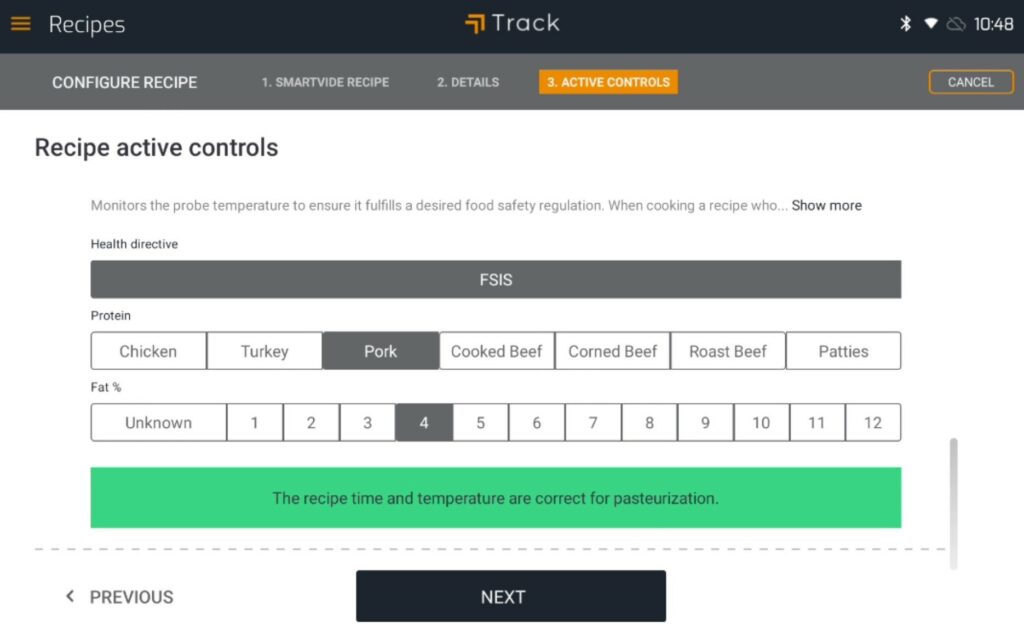

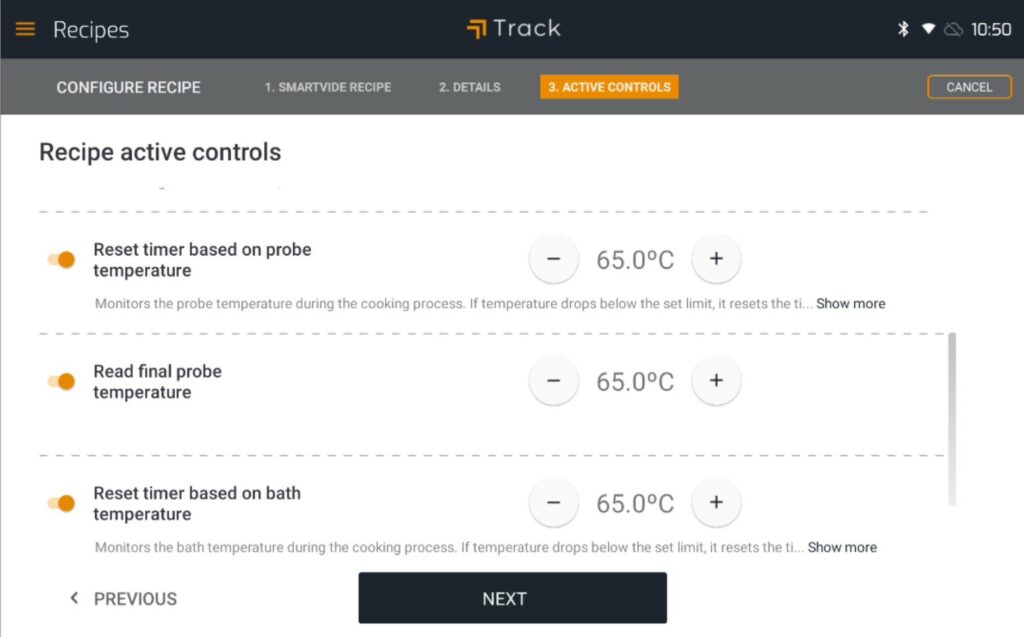

Active controls during processing

In relation to task 9 of establishing monitoring tasks for critical control points, active controls are additional parameters that can be established for each product or recipe in case they require further monitoring.

Additional controls can be set for water temperatures, probe temperatures, intermediate warnings during processing or pasteurization of a product.

Process controls during processing

Similarly, process controls refer to controls that are set to limit or enable actions when using the system. These may refer to product reuse, durations of warnings or permissions when extracting a product from water.

In short, HACCP is a preventive plan that aims to ensure the safety of food that is made available for human consumption. And in the case of low-temperature sous-vide cooking, Janby has developed a system that makes it possible to apply the different criteria for greater control.